Explanation

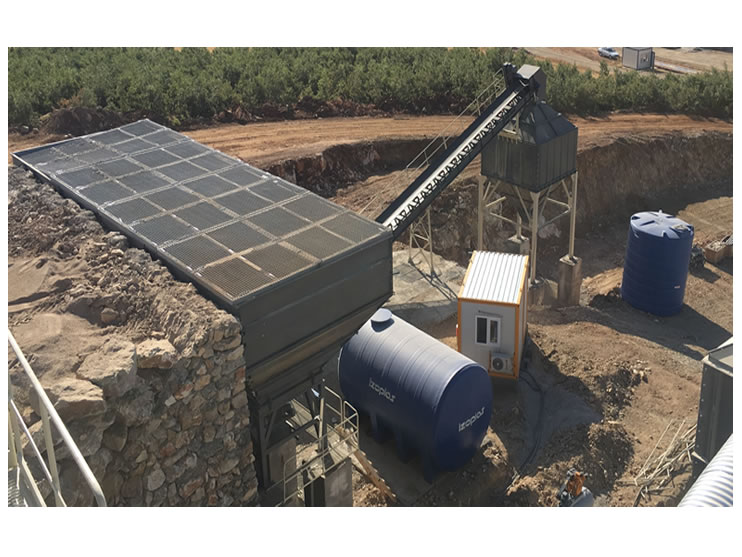

Mechanical Stabilization Plant is a group of machines that prepares the materials that can be used for all types of asphalt roads, airports and for maintenance purposes.

Sub-base material must be applied before asphalt construction in order to reinforce the base and repair the deformations on the existing asphalt surfaces.

Stabilization plants are the facilities which ensure that the aggregates whose dimensions are determined with technical specifications are properly and homogenously mixed with the determined amount and quantity of water in the mixing mixer and loaded onto the trucks.

Stabilization plants designed and manufactured by MTM with high strength and quality are successfully offered to our customers.

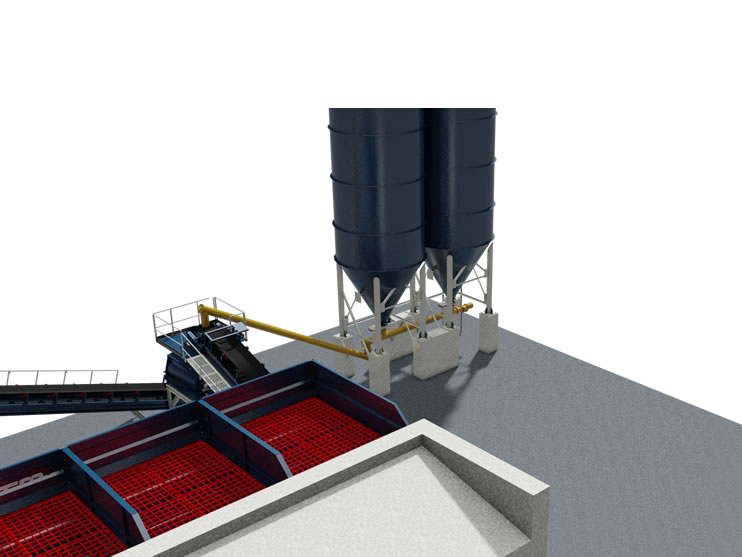

Aggregate Bins

-There are 4 or 6 aggregate bins, each with a capacity of 20-40 m³ depending on the required capacities mounted on a single heavy-duty main chassis.

-High quality vibromotors are used to prevent clogging in fine material aggregate bins even they have been designed with steep angles.

-Aggregate is fed to the system in a controlled manner with belt feeders operated by frequency converters properly placed under each bin.

-There is a collecting belt conveyor under belt feeders selected according to the capacity of the plant for conveying materials to the continuous mixer.

Features

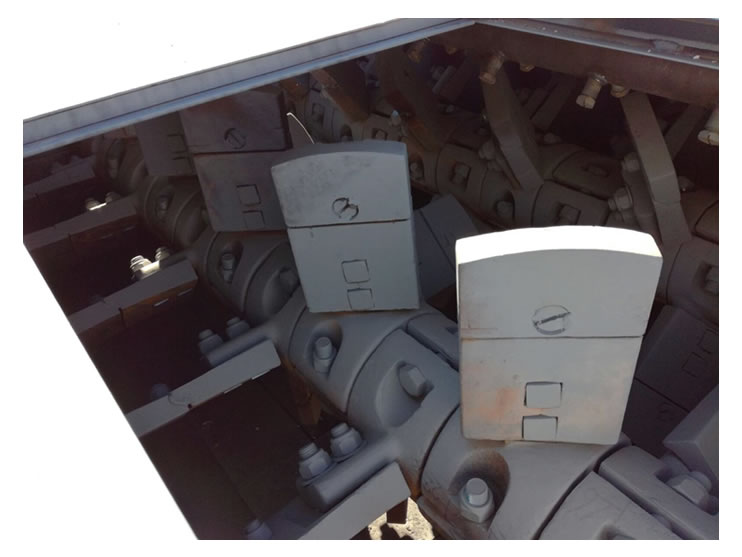

Continuous Mixer

A heavy-duty continuous mixer consisting of twin shaft with steel casted mixing arms and paddles is used to prepare a homogeneous mixture of aggregates.

-Wear Resistant Liners, Steel casted mixing arms and paddles are designed to be bolted type for ease of maintenance.

The water required for the mixer is distributed evenly into the mixer by means of a water pump which can be controlled by frequency converter.

Load Hopper

-There is a loading hopper with a capacity of at least 40 m³ for loading the stabilization material to the trucks automatically after the mixing work is completed.

-Pneumatic flap gate mechanism can be controlled from the separate control cabinet near the hopper.

-There is a compressor with suitable capacity and pressure for pneumatic system used for truck loading,

-High quality equipment and materials are used in all electrical systems and they are supplied by Group Schneider or Siemens.

Technical Values

| TYPE | MIXER VOLUME (m³) | POWER (kw) | Speed (rpm) | CAPACITY (mtph) |

|---|---|---|---|---|

| MSM-01 | 1 | 2x18.5 | 110 | 250 |

| MSM-02 | 1.35 | 2x30 | 116 | 350 |

| MSM-03 | 2.4 | 2x45 | 116 | 450 |