Grizzly Screens

Explanation

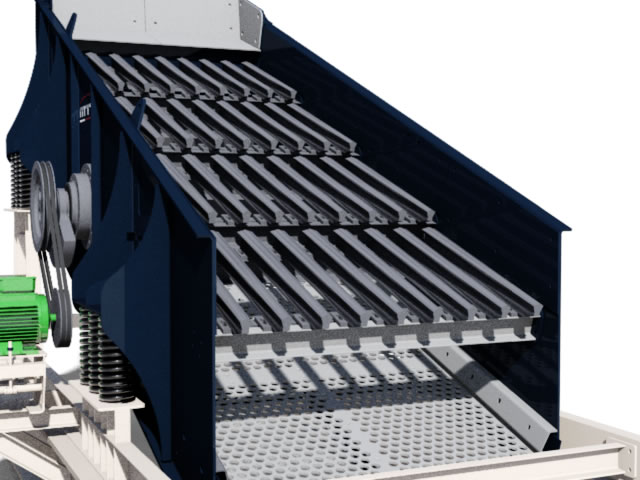

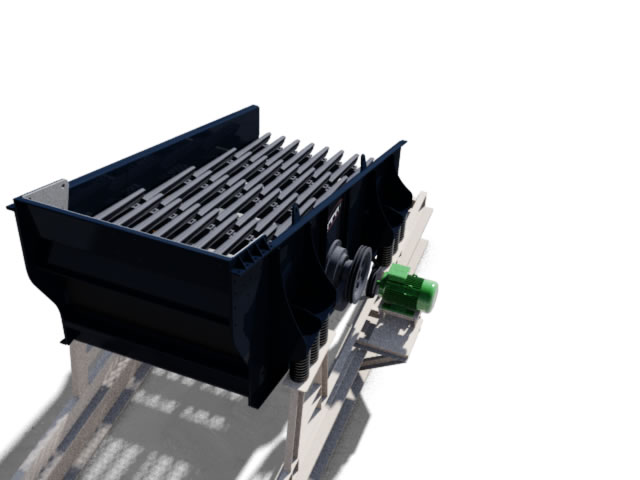

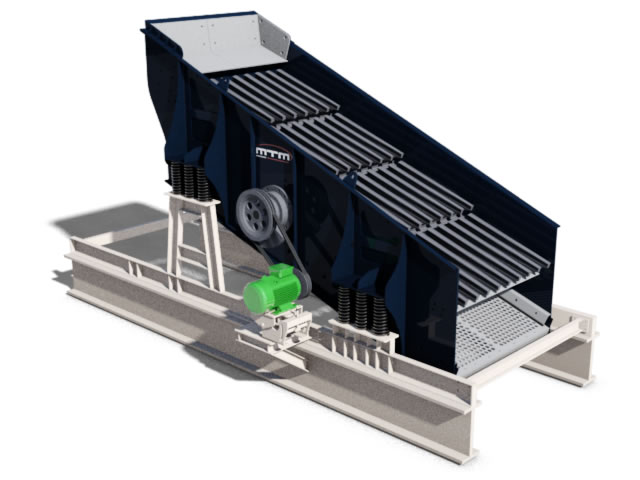

Grizzly Screens are very strong and robust screens suitable for the toughest high capacity applications. These screens have at least two grizzly sections, which allow them to operate under tough conditions as primary scalping or secondary pre-screening.

There are two types of grizzly screens; conventional circular throw and oval stroke screens which have a driving system on top of the gravity-centre to be protected from impact and abrasion.

Grizzlies used in these types of screens can be made from high manganese casted steel or high strength wear resistant metal sheets designed and produced by MTM Crushing&Screening

Features

Vibration-Resistant Main Assembly

MTM Grizzly Screens are manufactured from Class A single piece side plates and high strength grizzlies, decks and driving systems bolted to the main assembly.

Oil Lubricated X-Life Bearings

MTM Vibrating Screens enables easy maintenance and long life with their robust bearings running in oil splash lubricating system and no need for daily lubrication. They can be produced with grease lubricated driving system as optional.

Sliding Front Chute and Flap-Gate System

MTM Grizzly Screens are designed together with sliding front chutes and flap-gate systems. They can be moved without using any lifting equipment. You can control and combine the screened products easily with any ratio you wish by using flap-gate systems of the movable chutes.

Technicial Specifications

| Model | Screen Dimensions(mm) | Power (Kw) | Weight (kg) |

|---|---|---|---|

| MGS-1220 | 1200x2000 | 7,5 | 2700 |

| MGS-1235 | 1200x3500 | 11 | 5500 |

| MGS-1435 | 1400x3500 | 15 | 7200 |

| MGS-1640 | 1600x4000 | 22 | 10250 |