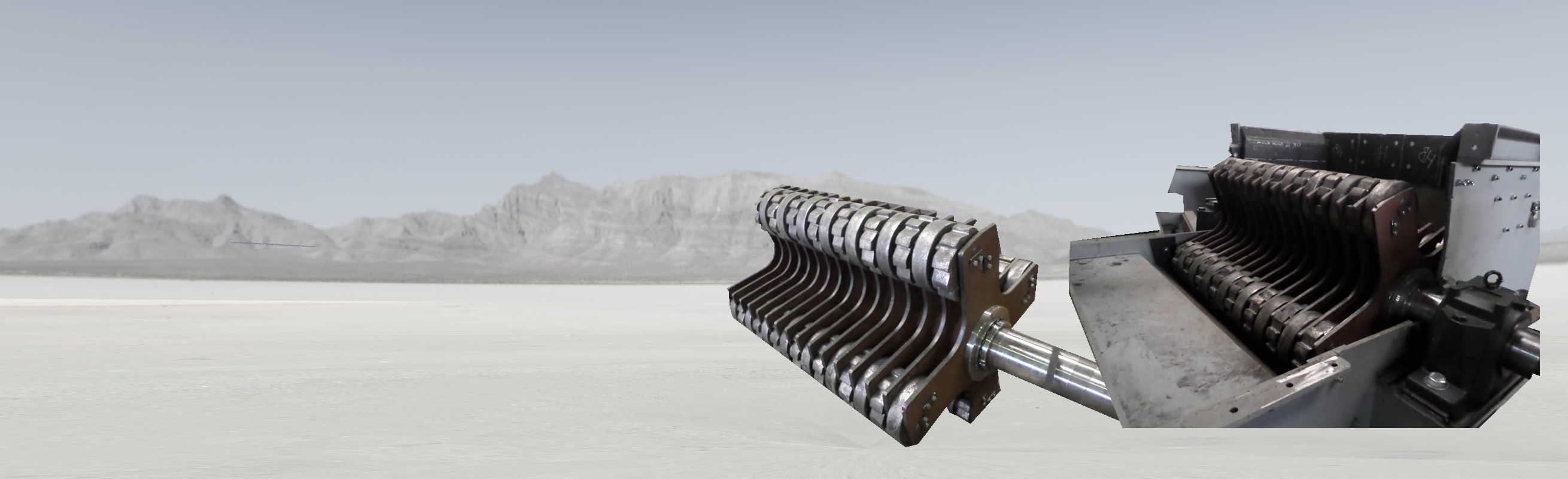

Ring Granulators

Explanation

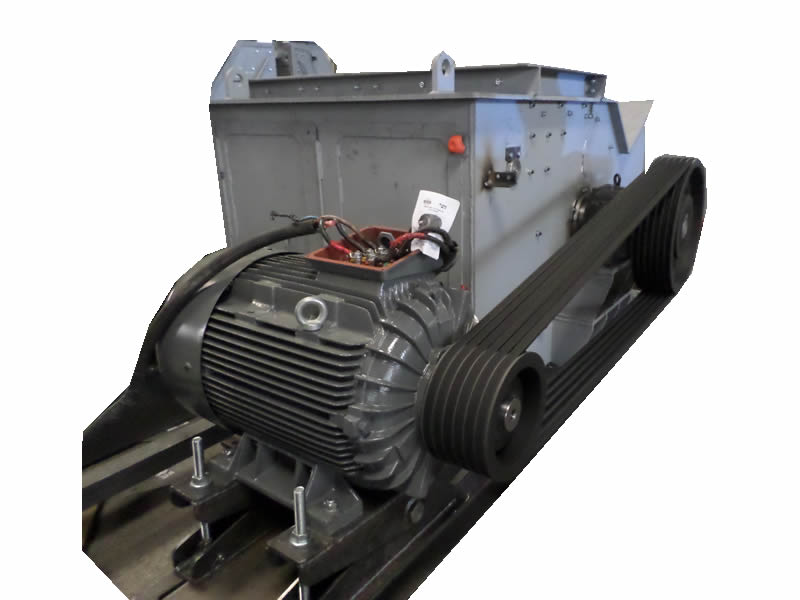

MTM Ring Rolling Granulators has a design resembles to hammer crushers except shape the discs and rings used in rotors instead of hammers. They are perfect crushers to crush coals producing less fines. They can take up to 300 mm feed and have a capability to reduce less than 25 mm or 50 mm in one pass according to cage and grizzly design.

The crusher has a cleaning door to remove tramped iron or uncrushable materials at the rear of the main assembly. They have also adjustment system to increase or decrease space between the rotor and grizzlies.

Features

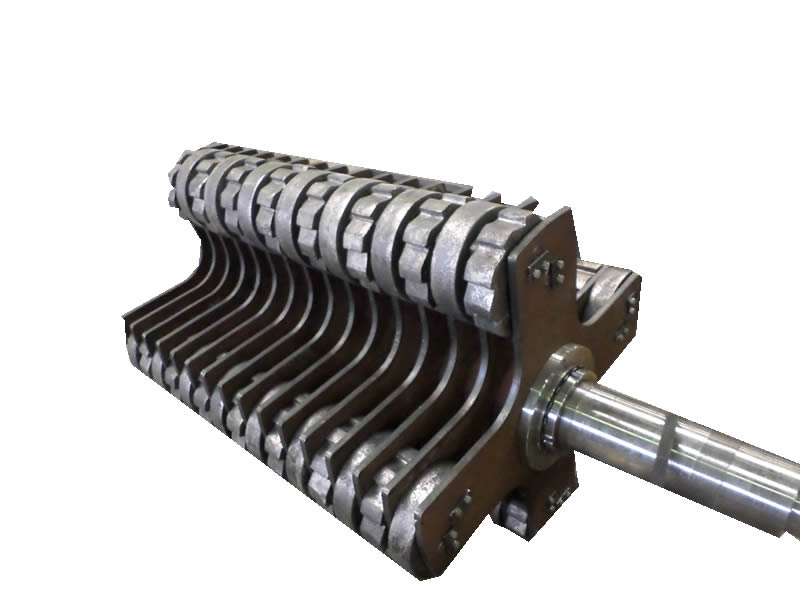

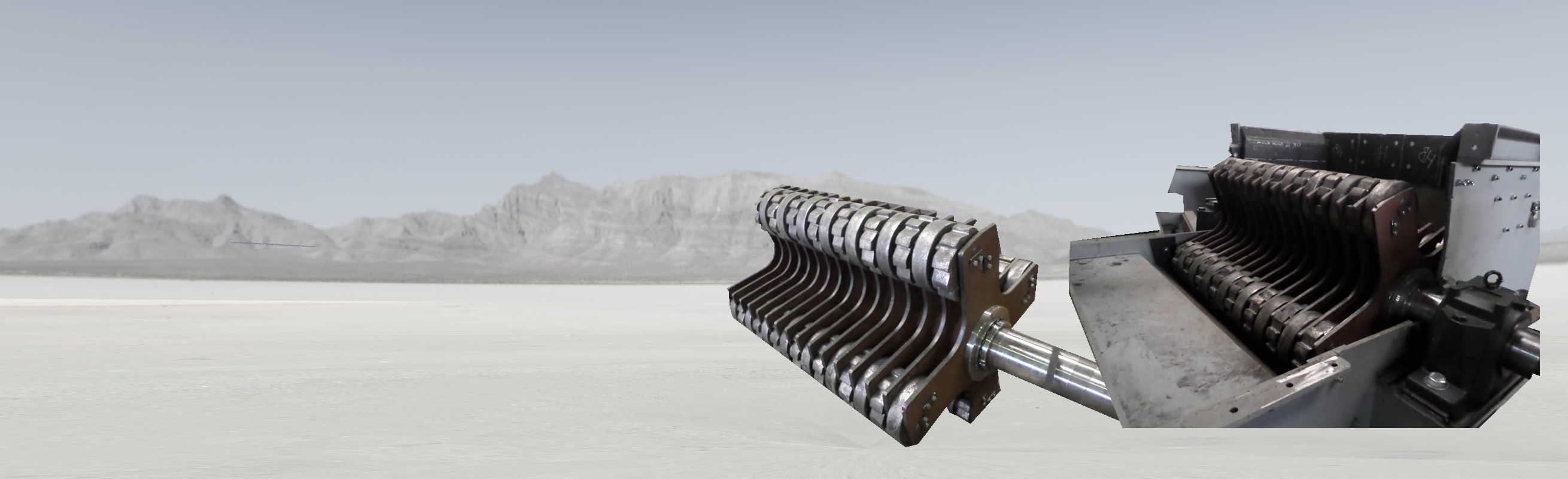

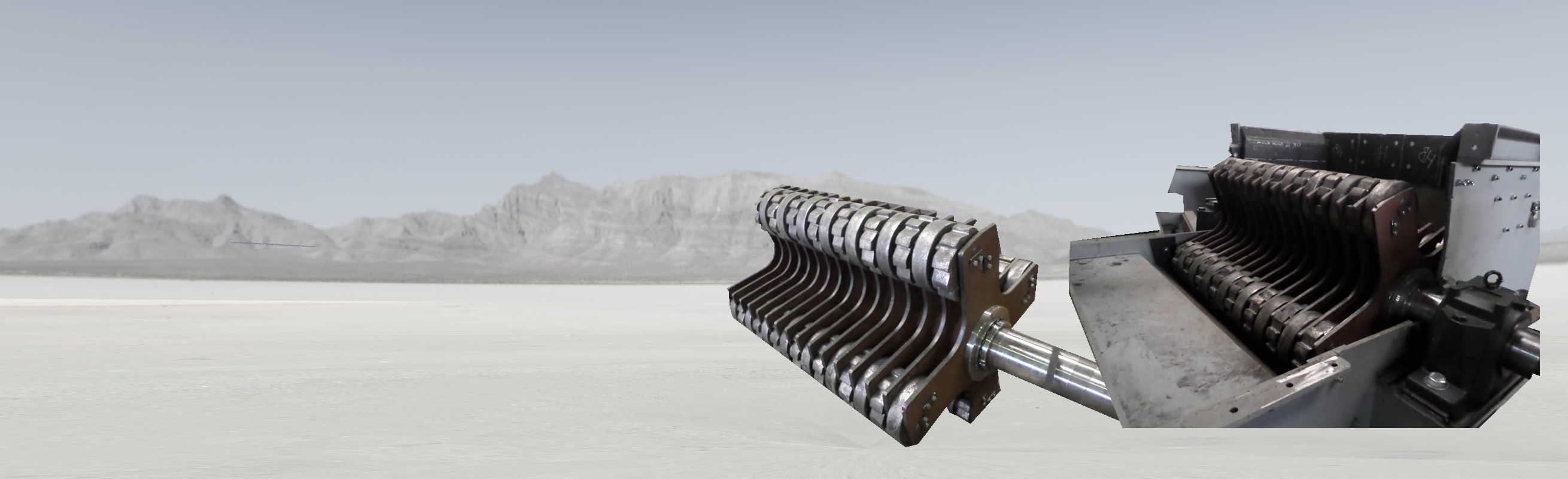

Grizzlies

There are high-manganese steel casted grizzlies placed under the rotor to get product with required size and fineness.

Rings

Specially designed and casted rings can be selected according to the characteristics of materials. Contact surfaces of rings with their shafts are machined to obtain smooth running and to prevent cracking. Some of the rings have cutting edges to get granular output.

Discs

Rotor Discs are strong parts which are made from High-Strength Sheet Metals. They are precisely machined and assembled to create rotor of the crusher.

Liners

High Impact and wear resistant liners are used for protection of main assembly. They can easily be replaced.

Technicial Specifications

| Model | Rotor Dimensions (mm) | Capacity (mtph) | Speed (rpm) | Power (Kw) | Weight (kg) |

|---|---|---|---|---|---|

| MK23 | 600x400 | 16-94 | 86 | 30 | 3700 |

| MK24 | 1000x550 | 34-250 | 60 | 75 | 10600 |