Explanation

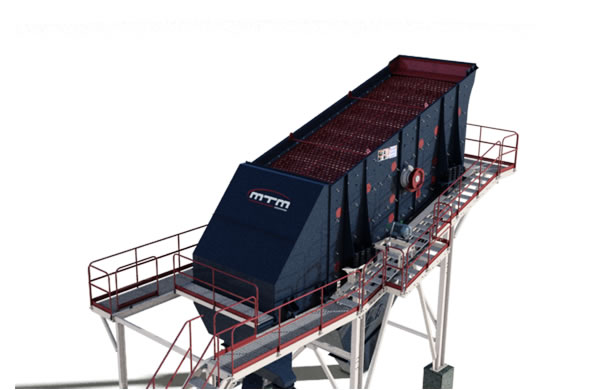

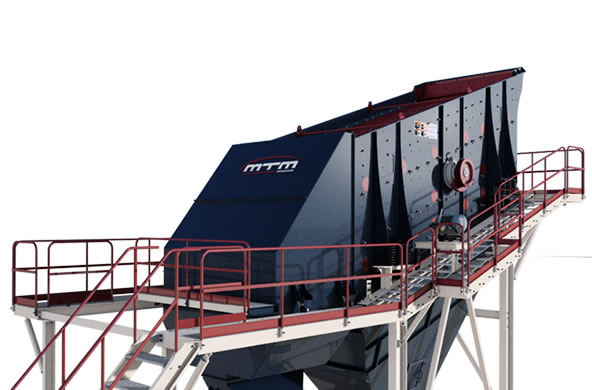

Vibrating Screens are most common type of screens used in Mining and Aggregate Production.

They are designed as inclined screens which classify materials on top of the screen clothes of intended apertures and work on the stratification principle.

They can also be called as “Circular Throw Screens” since the body of the screens makes circular movements resulted by the driving mechanism placed exactly at the centre of gravity.

Stratification is sifting the materials over the screen clothes so that finer material passes through the coarser and enabling particles smaller than the mesh of the screen to pass through.

MTM Conventional vibrating screens are designed and manufactured by using latest technologies and scientific techniques. There are screens as wide as 2,5 meters and long to 8 meters in MTM’s production range.

Remarkable Features of MTM’s Conventional Screens;

1.Weld free entirely bolted main assembly and drive mechanism.

2.Strong and Robust Bearings running in oil splash lubricating system and developed by SKF/FAG for Vibratory applications.

3. Special anti-clogging oil ventilation system

4. ASTM 4140 High strength eccentric driving shaft.

5.Class A single piece side plates

6.Reinforced Heavy-Duty Screen Decks

7.Non-Loosening Screen Clothes Tensioning System and heavy-duty special tensioning bolts.

8.Movable wheeled front chutes on rails simplifying maintenance and clothes replacement.

9-Stone-Box System increasing lifetime of Chutes

10.Rotatable Front Chute Extensions to make installations fast and easier.

11.Steel Chassis and Supports manufactured from High Strength Steel Channels

12. Anti-Slip, high-strength galvanized chassis platform grids with easy walking width.

13.Optional Screen Covers –Optional washing systems

14.Adjustable eccentric weights to increase or decrease driving force of the screen.

Features

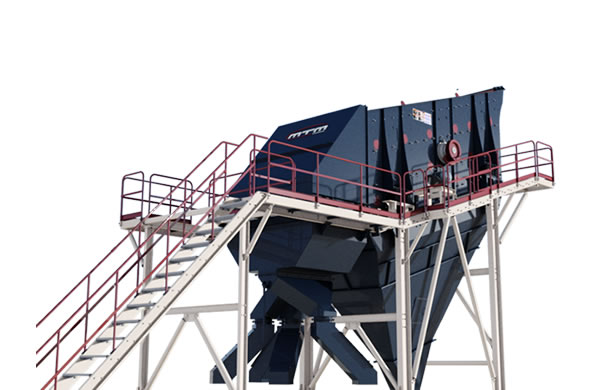

Vibration-Resistant Main Assembly

MTM Vibrating Screens are manufactured from Class A single piece side plates, decks and driving systems bolted to the main assembly.

Oil Lubricated X-Life Bearings

MTM Vibrating Screens enables easy maintenance and long life with their robust bearings running in oil splash lubricating system and no need for daily lubrication. They can be produced with grease lubricated driving system as well.

Sliding Front Chute and Flap-Gate System

To simplify the maintenance process and replacement of screen clothes, MTM Vibrating Screens are designed together with sliding front chutes and flap-gate systems. They can be moved without using any lifting equipment.

You can control and combine the screened products easily by using flap-gate systems of the movable chutes.

Technicial Specifications

| Model | Screen Dimensions(mm) | Power (Kw) | Number of Decks |

|---|---|---|---|

| MVS-1020 | 1000x2000 | 2,2-5,5 | 2-3 |

| MVS-1025 | 1000x2500 | 4 | 2-3 |

| MVS-1030 | 1000x3000 | 4-5,5 | 2-3-4 |

| MVS-1230 | 1200x3000 | 5,5 | 2-3-4 |

| MVS-1235 | 1200x3500 | 5,5 | 2-3-4 |

| MVS-1240 | 1200x4000 | 7,5 | 2-3-4 |

| MVS-1540 | 1500x4000 | 15 | 2-3-4 |

| MVS-1650 | 1600x5000 | 15 | 2-3-4 |

| MVS-2050 | 2000x5000 | 15-22 | 2-3-4 |

| MVS-2060 | 2000x6000 | 22-30 | 2-3-4 |

| MVS-2460 | 2400x6000 | 30 | 2-3-4 |

| MVS-2470 | 2400x7000 | 37 | 2-3-4 |