Explanation

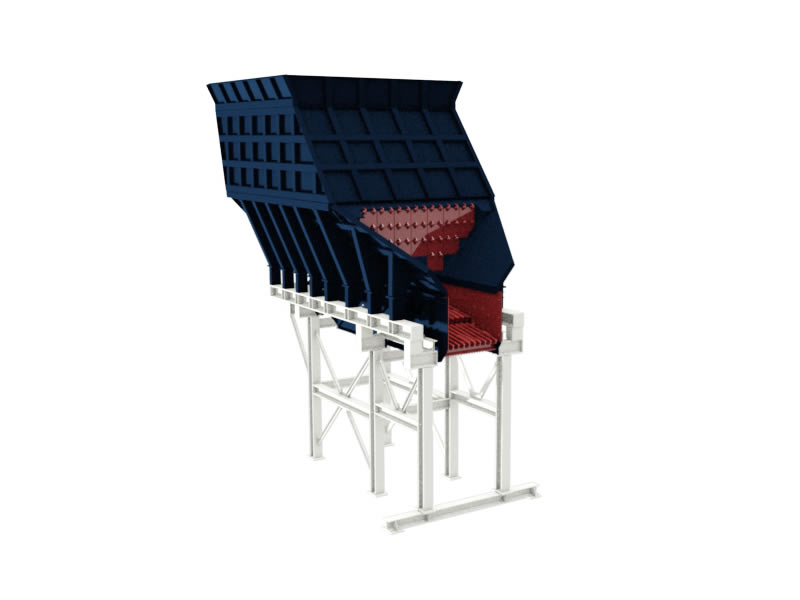

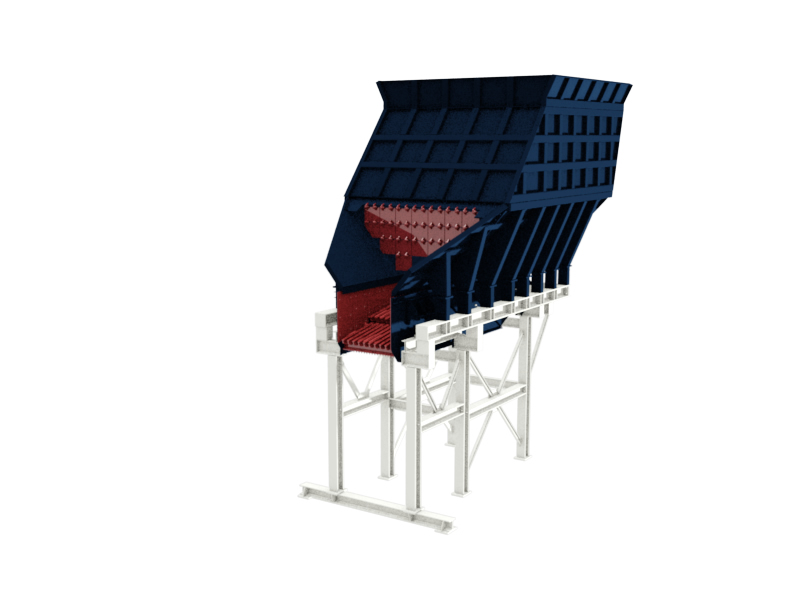

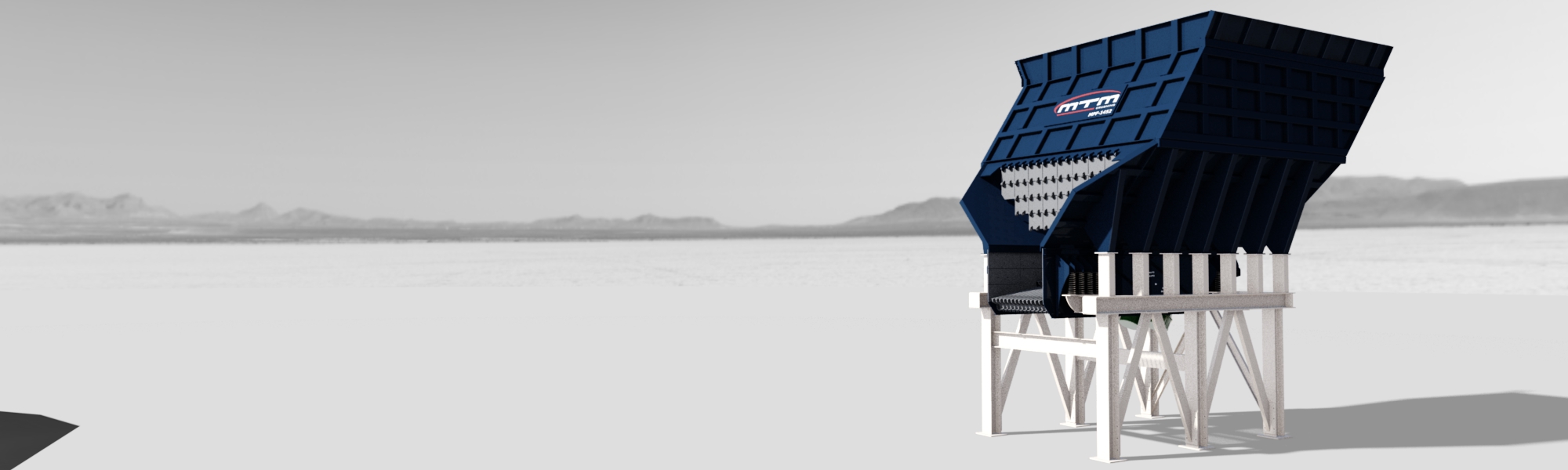

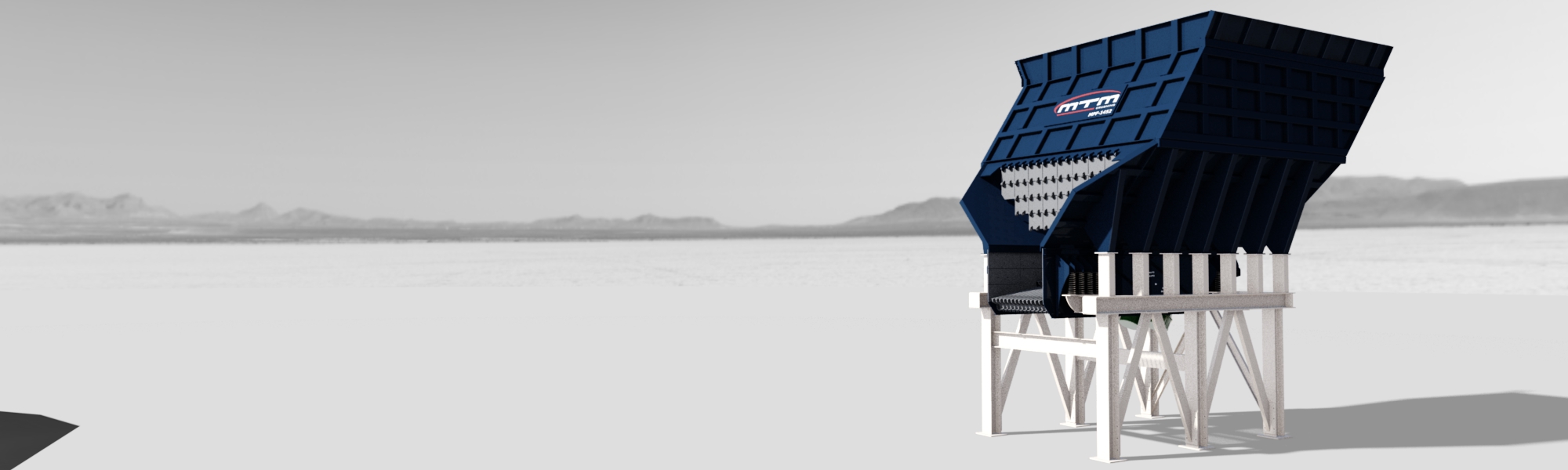

They are machines and equipment under the primary hoppers which initially feed raw materials to the primary crushers. MTM Primary feeders with their robust and very strong hoppers are selected appropriately by high experienced technical staff by considering all the properties of raw materials and required feeding capacities.

MTM Grizzly Feeders are manufactured with high qualities by using up-to-date technologies and work for our customers. Grizzly feeders are mostly used in crushing and Screening Plants since they have adjustable grizzly opening and need less maintenance and operational costs

Working principle of the grizzly feeders is to make feeder assembly vibrate with high amplitude by using unbalanced electrical motors.

Thanks to its adjustable working frequency by MCC, their performance is increased to maximum with respect to feed material features. They are very suitable for non-abrasive, dry, medium dense and non-sticky materials.

Features

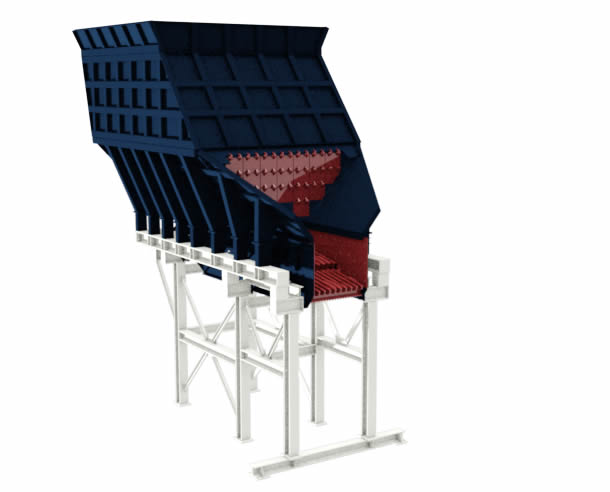

Vibromotors

They are unbalanced electrical motors used to make main feeder assembly vibrated with high frequency. They can be controlled with frequency convertor to increase feeding performances to higher levels.

Grizzlies

Grizzlies of the feeder are manufactured from Hardox wear plate and are designed to be adjustable for high efficiencies for by-passing materials.

Base and Side Liners

They are provided to customers with the options of HARDOX and ST52 wear-resistant plates

Vibromotors Chassis

Heavy Duty Chassis of the vibromotors is stress-relieved and assembled to the main body with bolts to make sure it’s robustness and to withstand severe vibrations.

Technicial Specifications

| MODEL | WIDTH (MM) | LENGTH (MM) | GRIZZLY LENGTH | BUNKER VOLUME (M³) | CAPACITY (mtph) | POWER | WEIGHT (KG) |

|---|---|---|---|---|---|---|---|

| MGF-0946 | 900 | 4600 | 2x750 | 20-25 | 150-200 | 2x7 | 4400 |

| MGF-1252 | 1200 | 5200 | 2x1000 | 25-30 | 200-300 | 2x9,8 | 5400 |

| MGF-1452 | 1400 | 5200 | 2x1000 | 40-60 | 300-600 | 2x11,5 | 8500 |