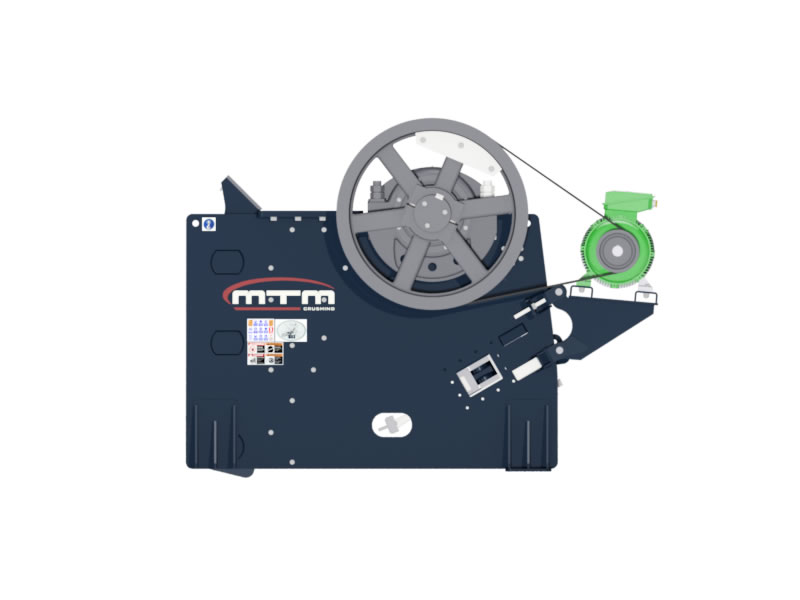

Jaw Crushers

Explanation

Jaw Crushers are most used and well-known crushers in the World and in Turkey. They can be used safely to crush all types of hard or medium-hard rocks and ore whether they are abrasive or not.

Product Range of MTM Crushing&Screening Company includes all size of primary and secondary jaw crushers manufactured by the latest

Technologies having a wide range of capacities.

MTM Jaw Crushers are at the service of our customers to be used in very hard conditions by their scientific mechanical design, high capacities and long life.

Features

Hydraulic Setting of the Jaws

Closed Side Setting of the Jaws can easily be adjusted in a short time by using hydraulic pistons and wedge mechanism. Adjustment can be done while crusher is still in operation by using this technology. There are no setting sheet plates in the system anymore…

Side Plates

Wear resistant high-manganese steel casted side plates are standard or HARDOX Metal Sheets can be used as requested.

Jaws

High-Manganese Steel Casted jaws of the crushers are specially designed with different profiles, tooth and pitches according to the characteristics of the materials to be crushed and can be reversed when wear occurs.

Primary Jaw Crushers Technical Specifications

| MODEL | Feed Size) | Capacity (mtph) | Speed (rpm) | Power (Kw) | Weight(kg) |

|---|---|---|---|---|---|

| MJC-63 | 610*380 | 20-80 | 330 | 30 | 6000 |

| MJC-65 | 650*500 | 25-100 | 330 | 45 | 7000 |

| MJC-90 | 900*650 | 50-250 | 293 | 75 | 11500 |

| MJC-110 | 1100*850 | 100-310 | 228 | 132 | 33000 |

| MJC-130 | 1300*1000 | 275-610 | 210 | 160 | 43000 |

| MJC-140 | 1400*1000 | 285-700 | 213 | 200 | 51000 |

Secondary Jaw Crushers Technical Specifications

| MODEL | Feed Size) | Capacity (mtph) | Speed (rpm) | Power (Kw) | Weight(kg) |

|---|---|---|---|---|---|

| MSJ-60 | 600*300 | 5*40 | 333 | 22 | 4000 |

| MSJ-90 | 900*200 | 10 ~ 80 | 330 | 30 | 6000 |

| MSJ-110 | 1100*350 | 40-150 | 327 | 75 | 11000 |