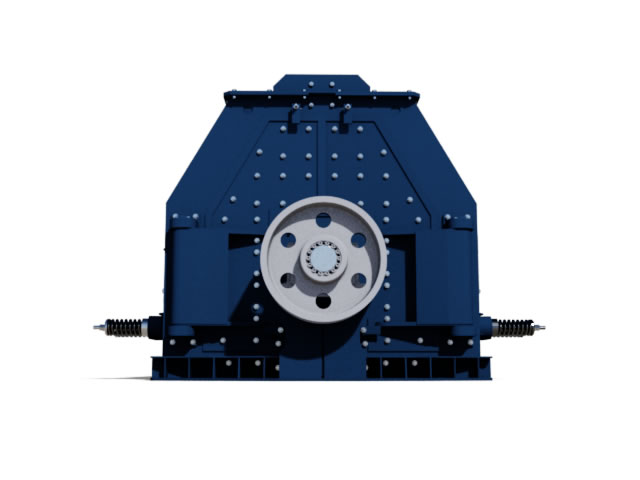

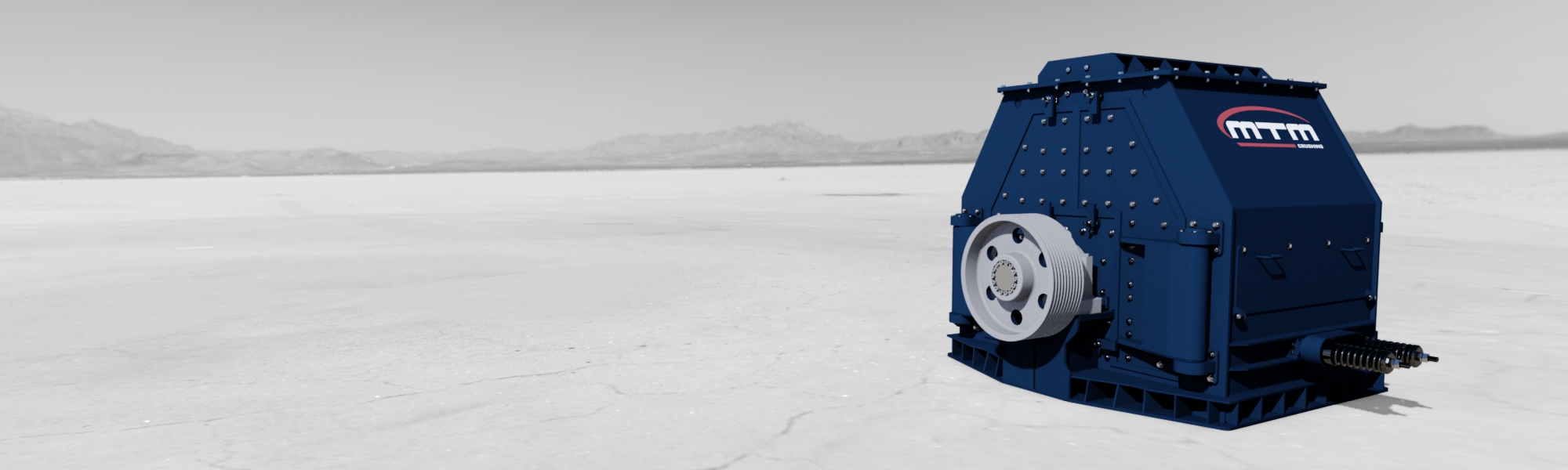

Tertiary Impact Crushers

Explanation

After secondary crushing stage, oversize material is directed either back to the secondary stage or to be crushed and shaped further at the tertiary stage to get much finer high-quality products. Since the materials are reduced to smaller size, specially designed, strong and faster machineries should be used for tertiary crushing stage.

Material size and output gradations are affected by the type of tertiary crushers selected and used. That’s why we recommend our customers to get a professional aid when they have to select a tertiary crusher for their plants.

Features

Main Assembly

MTM Tertiary Crushers are designed to maximize crushing efficiency with their specially designed main assembly and breakers. Thanks to their robust assembly and adjustable breakers, they are very suitable to get products which satisfies our customers’ requirements related with the quality, shape and size.MTM Crushing&Screening Company designs and manufactures standard or specialized tertiary crushers to meet capacities and features asked by our customers.

Rotor

Specially designed anti-wear coated Rotors assures long-life to our customers.

Liners and Wear Parts

Casted Parts with High Manganese and Chromium options depending the characteristics of materials are used in Main Assembly and rotors.

Bearings

Long life heavy-duty SKF Bearings and thermal sensors are used in housings of the rotor. FAG Bearings are optional for our customers

Optional automatic lubrication system makes maintenance easy for our customers.

Technicial Specifications

| MODEL | Rotor Dimensions (mm) | Capacity (mtph) | Rotor Speed (rpm) | Power (Kw) | Weight(kg) |

|---|---|---|---|---|---|

| MTC-1105 | 1100*500 | 80-100 | 740-900 | 160 | 10000 |

| MTC-1110 | 1100*1000 | 100-200 | 740-900 | 250 | 16000 |

| MTC-1115 | 1100*1500 | 200-250 | 740-900 | 315 | 19000 |

| MTC-1318 | 1300*1800 | 300-350 | 645 | 500 | 33000 |

| MTC-15 | 1400*860 | 80-140 | 740-900 | 160 | 15500 |

| MTC-16 | 1400*1200 | 120-180 | 740-900 | 250 | 21000 |